Technical features:

Automatic control of the whole production process through intelligent program can realize continuous operation, with fault alarm, display and automatic interlock shutdown functions, and communication interface can also be equipped according to customer needs to realize real-time monitoring, remote diagnosis and networked management of the entire production line.

Scope of application:

It is applicable to various packaging bags, such as paper bags, plastic bags, woven bags, etc. It is widely used in waterproof building materials, feed, agrochemical, fertilizer, seeds, rice, grain, plastic particles and other industries.

Technical parameters:

1. Weighing range: 20-50kg/package

2. Weighing accuracy: ± 0.2%

3. Production capacity: 800-1200 packages per hour

4. Power supply: 380VAC/220VAC 50HZ, ± 10%

5. Control power supply: 24VDC

6. Control air source: 0.5-0.8MPa

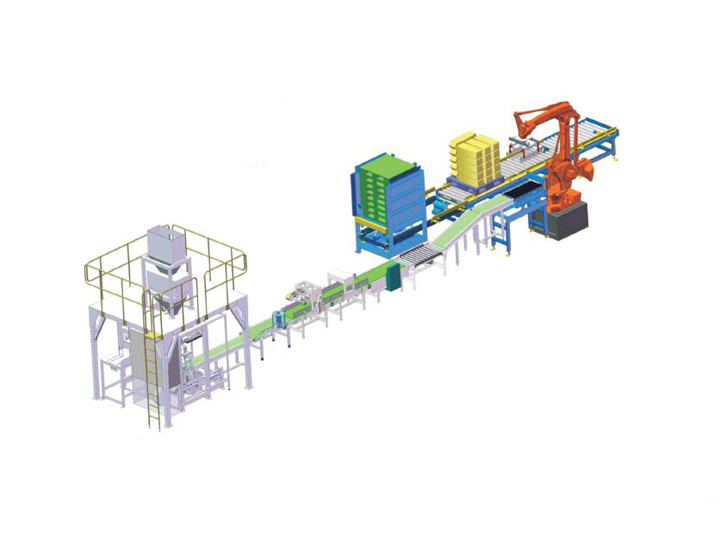

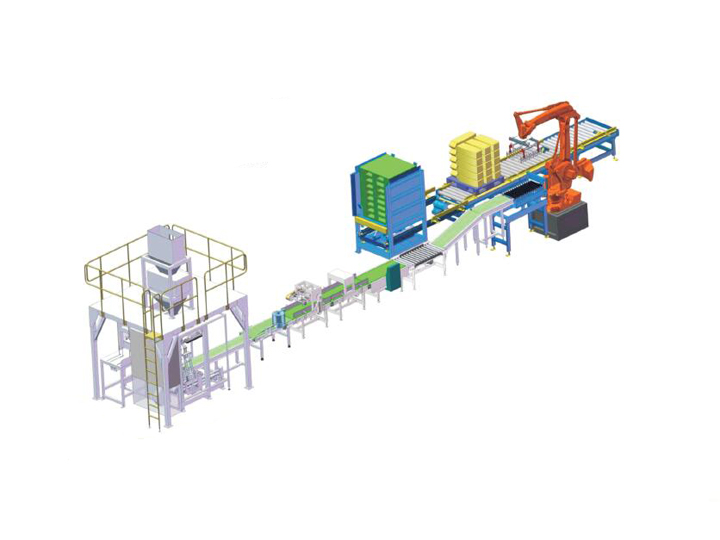

Technological process:

Automatic bag loading → automatic bag suction and clamping → automatic weighing and packaging → automatic bag feeding and sewing → automatic bag pouring → automatic bag shaping and pressing → robot stacking → automatic pallet warehouse → forklift