Product introduction and features:

IHH series chemical centrifugal pump is the replacement of IH type chemical process pump. The performance parameters and installation dimensions of the modified series are the same as those of the IH pump. The product complies with GB/T5662 Marking, Performance and Dimensions of Axial Suction Centrifugal Pump (16bar).

IHH pump absorbs the appearance design of XA pump suspension and designs reinforcing ribs on the pump body, which makes the pump beautiful, safe, reliable and long service life.

IHH pump suspension components: five suspension covers the whole series, ensuring fast delivery and minimum inventory.

IHH pump shaft seal form: according to user needs, it can select packing seal, single-end non-balanced mechanical seal, single-end balanced mechanical seal, single-end back-to-back non-balanced mechanical seal, double-end non-balanced mechanical seal and double-end balanced mechanical seal. The seal is safe, reliable and has a long service life.

The pump body and impeller adopt wax pattern precision casting, with higher efficiency and better appearance quality than IH.

The coupling generally adopts elastic pin coupling, and users can choose lengthening diaphragm coupling and other connection methods according to their needs.

IHH open impeller enhances the conveying capacity of solid particles and is not easy to block. Its performance parameters and installation dimensions are the same as IHH closed impeller structure.

Product mark and number of this series of products: (H) XK06-003-00039.

Purpose:

It is mainly used for transporting corrosive or non-polluting media without suspended particles in petroleum, chemical, synthetic fiber, power station, metallurgy, food-grade and pharmaceutical industries.

Scope of work:

Medium temperature:- 20 ℃ < T < 105 ℃

Flow:Q=3.1-1000 (m ³/ h)

Speed:n=1450r/min 2900r/min

Lift:H=3.1-132.5 (m)

^Large working pressure:1.6MPa

Rotation direction of the pump:from the direction of the motor to the clockwise direction of the pump

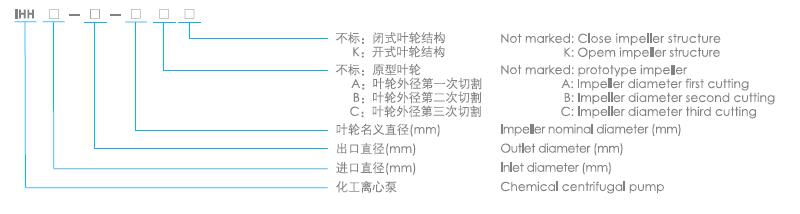

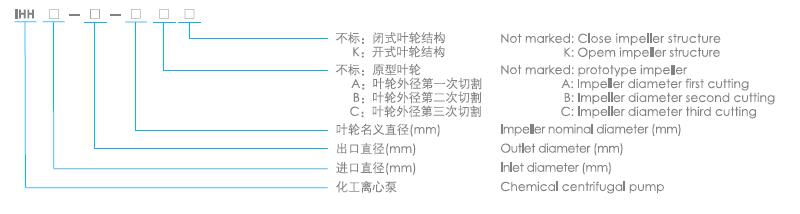

Model definition: